Digitalization, one of the most important pillars of increasing productivity in production, correct production planning, predicting or minimizing breakdowns and stops, is a part of Industry 4.0 that we hear a lot.

Plastic Injection Production Industry 4.0

In particular, in the plastic injection sector, due to the high variable production, high production numbers and high human dependence, predictions become difficult and the productivity rate varies downwards. The best way to optimize this would be to take as much data as possible from the injection molding machines and record them in an understandable form and then present a meaningful analysis.

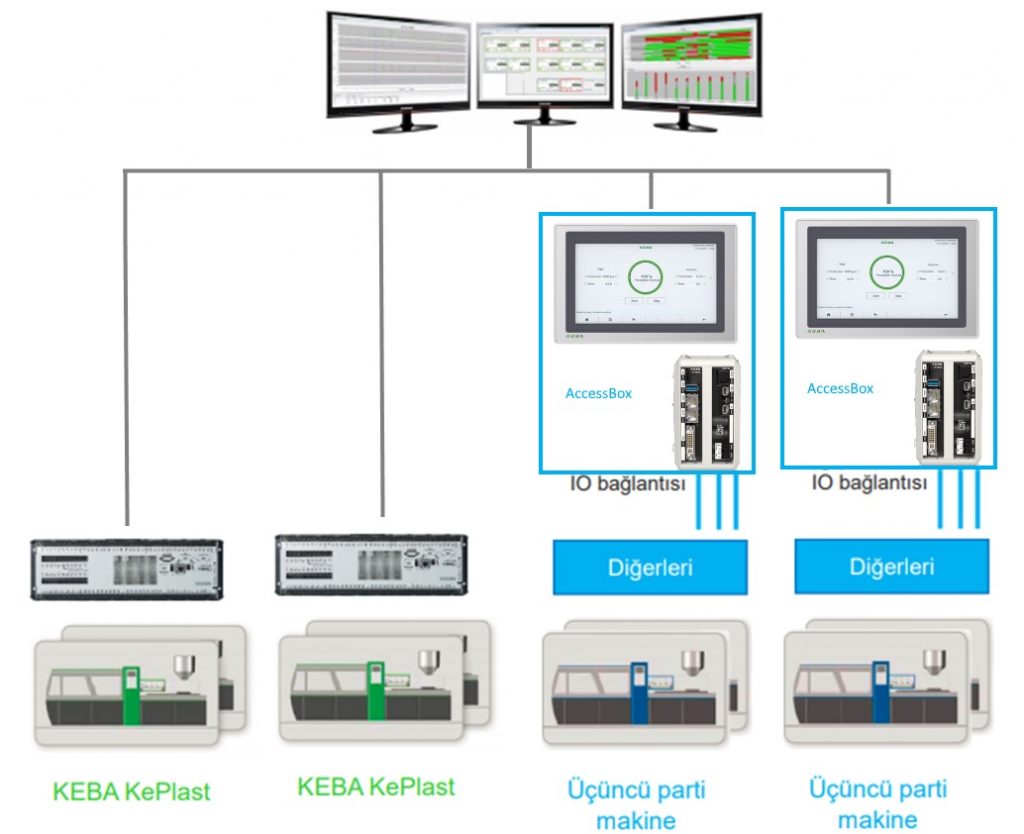

As ROS Mühendislik, we collect data from all plastic injection machines in the production area, interpret and save them. While the plastic injection machine control device is KEBA, it can receive very detailed data, while the data collected in other control brand control devices varies according to the brand and model. From the machines that do not have any compatibility with Industry 4.0, we use the "ACCESS BOX" to analyze the machine by following the movements of the machine with physical connections.

To summarize the configuration briefly;

Machines are gathered in an ethernet switch with ethernet cables and connected to the "Server" computer. For the machines that do not have an Ethernet port, the whole connection is completed from the ethernet port of the "ACCESS BOX" that we have installed.

As ROS Mühendislik, we are at your side for the most convenient and efficient system as your digital transformation partner and consultant in plastic injection.

For more information please contact us info@rosmuhendislik.com